How could I have been so stupid to think creating a web-based apparel app is a good idea?

Fact is, I still think it’s a good idea – maybe even the best idea I’ve ever had. But, oh boy, has it been a rocky road or – on a more positive note: lots of room for growth and learning. Especially for an apparel designer.

It was early 2014 when I found myself a managing partner at an Apparel Design and Sourcing Agency. While I did all the front end stuff, the strategy and design process with clients, my partner manned the back-end: sourcing, factory relationships, production and getting the goods into the various warehouses. All the tasks in between, development, tech design, pattern making, material development and research, were done by experts who had been in the industry for many years in brands like Nike, Columbia Sportswear, Adidas, Eddie Bauer, Lucy, Icebreaker, Castelli, … just to name a few.

But even though, the paperwork was absolutely insane. And keeping track of all the details was closer to a nightmare.

I am a recovering perfectionist and while I wanted to know where every style was in the process, it was impossible to stay on top of it.

Unfortunately, small mistakes can have a big impact. At times it felt that any mistake that could happen would.

For example, we got a bulk delivery of bras for a client in an unflattering flesh color that should have been bright pink. We dug deep into the vast history of excel sheets that were stored on our server to see what happened, why it happened and who made the error to figure. My partner, in the meantime, was negotiating with the factory and material mill to find out where the pickup happened and who would shell out the funds to reproduce in the correct color. I knew that a transposed digit in the Pantone color standard code could have been the culprit. Honestly, anyone could have messed up here. But was a stupid error not avoidable in this day and age?

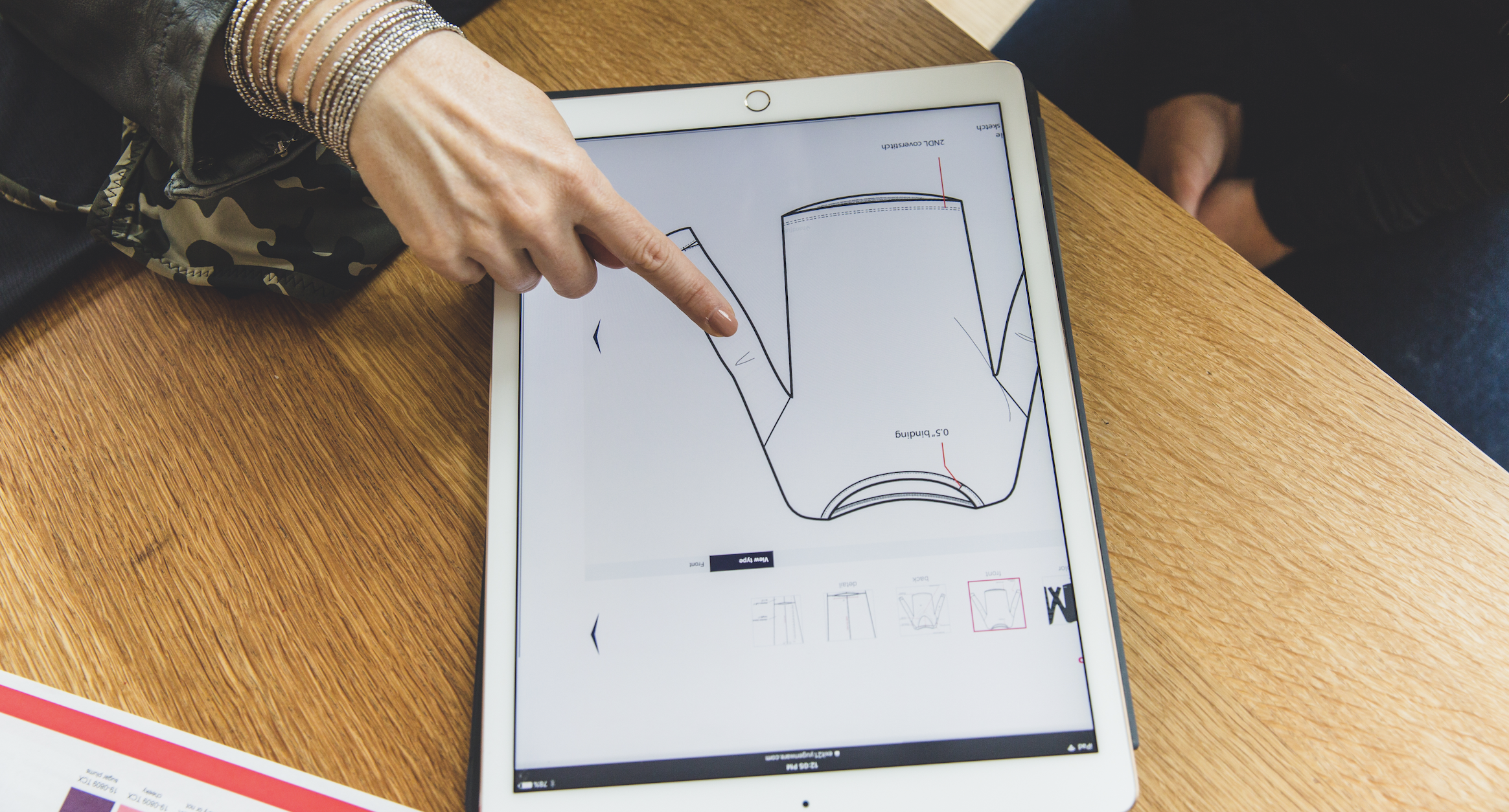

While this wasn’t the only problem we ran into, the issue to me was bigger: I felt it a complete waste of time, money and energy to hire experienced contractors so they edit, correct and manage a bunch of excel sheets and keep them updated in case of a material change. Can you imagine that a material detail change for a well x-merchandised collection consisting out of multiple styles required the developer to remember each style that uses that particular fabric, be it as main or even just trim application, and copy-and-paste the new information into several excel sheets? Then, keep track of all that and update the factory merchandisers and mills. A lot can happen with repetitive tasks like that. A lot of unpleasant things. And as a side effect, the team got burnt out over the pressure to avoid any errors without the help of a more sophisticated system to keep track or flag errors.

A google search didn’t come up with a tech solution that looked promising or affordable for a startup like us. Excel was the most affordable and widely used solution. Based on my knowledge in the industry – having spent over a decade designing for big brands like Nike, Adidas and Columbia Sportswear myself – and having been exposed to PDM (Product Data Management) or PLM (Product Line Management) systems that were in use, I wondered that there should be a better way of capturing the information.

I couldn’t stop thinking that this needed to change!

So I set out to create a solution that would be super smart, easy to learn and affordable too.

But first I needed to find someone who could help me build it.

The only person I knew turned out the best person on the planet to build a complex but easy to use beast: Leon Yeh.

I met Leon while working out of an incubator space in Portland, OR. He had shown me a very visual online catalog solution he had created but at that time I didn’t know how I could ever make use out of it.

I thought – I’ll run this idea past him and if he throws me out because it is so complex, then I will put this idea to rest. But he didn’t. He said it could be done and after some huddling, I wrote my first check and pulled the trigger.

Leon had decades of engineering experience under his belt and I soon found out he birthed similar solutions for the automotive industry (Toyota) and aerospace (Northrup Grumman). He had the knowledge of what mistakes to avoid but most of all he was hungry to create a fresh piece of software (funny side note: for the longest time, I used to spell the word ‘softwear’) that would surpass any system he had created before and he wanted to use the newest technology possible.

Besides my experience, his tech know-how, we had another superpower: We could test the system in real time in a real agency setting and have it be refined by the users for what works best for THEM. The team would use it with factories across Asia and we would gain their feedback and insight too.

After 8 months of creation, we were ready to roll it out at Exit21. And oh boy were we in for a ride. It was intense months for errors to happen, for information to disappear that had to be recreated in the middle of the night because a developer was in Asia working with the factories and the data was swiped clean.

‘Mistakes make your brain grow’ is what teachers write on their boards these days. Because we can only learn from the mistakes we make. And they did happen – especially during the process of refining the workflow feature and how the flow of information is captured transitioning between the various prototype stages.

If you want to see ngnINE in action or want to test it out, send me an email and we’ll show you around. I’ll even set you up with a free account: daniela@ngnine.io